-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Power steering cross feed rack lines/fittings?

Discussion in 'Technical Chat' started by skigan, Jun 1, 2020.

FIPG get the real stuff or is there better cheaper?

FIPG get the real stuff or is there better cheaper? Heater fan makes noise

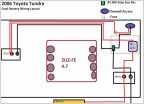

Heater fan makes noise Can you Connect a BS ML-ACR to a Bus Bar? Wiring Layout Help Needed.

Can you Connect a BS ML-ACR to a Bus Bar? Wiring Layout Help Needed. Smittybilt XRC wiring

Smittybilt XRC wiring Hella 1000 Install - Switch Works But Not Lights

Hella 1000 Install - Switch Works But Not Lights IPad for back up camera?

IPad for back up camera?