-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Leaf shackle mount frame repair...

Discussion in '1st Gen. Tacomas (1995-2004)' started by Boomcat12b, Nov 13, 2020.

Easy way to make corner lights blink without cutting any factory wiring

Easy way to make corner lights blink without cutting any factory wiring Raptor liner roller

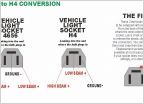

Raptor liner roller H4 Headlights direct plug and Play or need harness?

H4 Headlights direct plug and Play or need harness? These rotors?

These rotors? Replacing Lower Ball Joints and Carrier Bearing Parts check

Replacing Lower Ball Joints and Carrier Bearing Parts check Time to replace CV Axle, Need recommendations for replacement

Time to replace CV Axle, Need recommendations for replacement