-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

driveline angle corrections when lifted " the light fix"

Discussion in '3rd Gen. Tacomas (2016-2023)' started by dyna962007, Sep 18, 2017.

Page 1 of 2

Page 1 of 2

2017 Tacoma Limited Edition TONNEAU COVER

2017 Tacoma Limited Edition TONNEAU COVER Suspension Corrosion

Suspension Corrosion 3rd Gen MT Drain Plug

3rd Gen MT Drain Plug Is this usable as a front recovery point? Asking for a friend

Is this usable as a front recovery point? Asking for a friend Tailgate liner/protection. Best way to attach to inner tailgate.

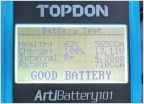

Tailgate liner/protection. Best way to attach to inner tailgate. AGM Battery Question - New Battery at 63% Health

AGM Battery Question - New Battery at 63% Health