-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

Quick Links: Where do i put my transmission temp sensor

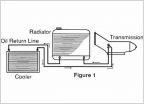

Where do i put my transmission temp sensor  TRANSMISSION . Transmission coolers for all Toyotas ... Write up with many pictures

TRANSMISSION . Transmission coolers for all Toyotas ... Write up with many pictures  Scan tool recommendation for trans temp detect mode when changing fluid

Scan tool recommendation for trans temp detect mode when changing fluid  Which portable power station for my new fridge?

Which portable power station for my new fridge?  Using 1000w inverter to charge portable power station...

Using 1000w inverter to charge portable power station...  New head unit with wifi reception?

New head unit with wifi reception?

Dielectric greasing electrical connections?

Discussion in 'Technical Chat' started by x2468, Jul 10, 2012.