-

Welcome to Tacoma World!

You are currently viewing as a guest! To get full-access, you need to register for a FREE account.

As a registered member, you’ll be able to:- Participate in all Tacoma discussion topics

- Communicate privately with other Tacoma owners from around the world

- Post your own photos in our Members Gallery

- Access all special features of the site

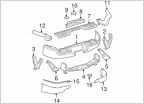

Basic Bumper Crane.

Discussion in 'Armor' started by pursang, Aug 11, 2020.

Mud flaps on high clearance rear bumper

Mud flaps on high clearance rear bumper How to Keep Hi-Lift Jack from Sliding

How to Keep Hi-Lift Jack from Sliding Help me find a bumper

Help me find a bumper Peforway Winch Bumper on Amazon. Anyone try it???

Peforway Winch Bumper on Amazon. Anyone try it??? Cali Raised Sliders - why go bedliner over powder coat?

Cali Raised Sliders - why go bedliner over powder coat? 2nd Gen Front Bumper Center Section .DXFs - Free Use

2nd Gen Front Bumper Center Section .DXFs - Free Use